The readability of cryogenic labels in cryogenic conditions

Split

How to ensure legibility of cryogenic labels under cryogenic conditions

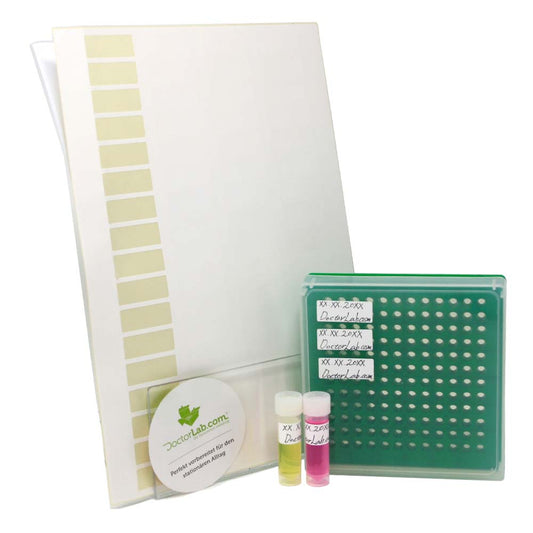

In medical research, cryogenic labels are used for identification and traceability of samples stored at extremely low temperatures. To ensure that labels perform their function, they must remain legible under cryogenic conditions. In this article we will look at how to ensure readability of cryogenic labels in cryogenic conditions.

What are cryo labels?

Cryogenic labels are specially designed labels that remain readable at extremely low temperatures of up to -196°C. These labels are made from materials that remain flexible and durable even under these conditions. Cryogenic labels are used in medical research to identify samples and ensure their traceability.

Challenges in readability of cryogenic labels

Cryogenic labels must withstand various challenges to remain readable under cryogenic conditions. Here are some of the challenges:

1. Condensation

At cryogenic temperatures, air condenses and moisture collects on the surface of cryogenic labels. This condensation can cause labels to peel off or become unreadable.

2. Material quality

The material from which cryogenic labels are made must be flexible and durable to withstand cryogenic conditions. If the material is not of high quality, it may break or become brittle, resulting in poor readability.

3. Labeling

The writing on cryogenic labels must be permanent and must not fade or smudge. If labeling is not clear and legible, samples cannot be properly identified and traced.

Tips for improving readability of cryogenic labels in cryogenic conditions

1. Use high quality materials

The quality of the materials from which cryogenic labels are made is crucial to their readability under cryogenic conditions. It is important to choose labels made from materials that are flexible, durable and resistant to condensation.

2. Avoid excessive labeling

If labels are inscribed with too much information, it can become difficult to keep them legible under cryogenic conditions. It is best to label labels with only the most important information to ensure clear readability.

3. Use of special inks

To ensure that cryogenic labels remain readable in cryogenic conditions, special inks must be used. These inks must be able to withstand extremely low temperatures without fading or smudging. There are different types of inks recommended for use with cryogenic labels. These include, among others:

- Ethanol Resistant Inks: These inks are specifically designed for use with cryogenic labels and can be used in temperatures down to -196°C. They are also resistant to ethanol, which is commonly used in sample cleanup.

- Thermal Transfer Inks: These inks are heat resistant and can be used when using thermal transfer printers. They are ideal for labeling samples stored at extremely low temperatures.

- Laser Inks: These inks can be used when using laser printers. They are heat-resistant and can be used at extremely low temperatures.

4. Using clear and durable labels

To ensure that cryogenic labels remain readable in cryogenic conditions, it is important to use clear and durable labels. Labels should be made from materials that can withstand extreme temperatures without losing adhesion or legibility. Some materials recommended for cryogenic labels include:

- Polypropylene: Polypropylene is a durable material that can be used at extremely low temperatures. It is resistant to moisture and chemicals and maintains readability and adhesion.

- Polyester: Polyester is another durable material that can be used at cryogenic temperatures. It is resistant to moisture, chemicals and abrasion and maintains readability and adhesion.

- Vinyl: Vinyl is a flexible material that can be used at extremely low temperatures. It is resistant to moisture and chemicals and maintains adhesion and readability.

5. Regular inspection and maintenance of cryogenic labels

To ensure cryogenic labels remain readable in cryogenic conditions, it is important to inspect and maintain them regularly. This includes checking the readability of the labels and their adhesion. If labels are illegible or have fallen off, they should be replaced to ensure sample integrity and traceability.

Conclusion

In summary, cryogenic labels are specifically designed for the identification and traceability of samples stored at extremely low temperatures. However, the readability of cryogenic labels under cryogenic conditions is a challenge that influences various factors such as condensation, material quality and labeling. To ensure that cryo labels remain readable in cryogenic conditions, high quality materials, special inks and clear and durable labels should be used. In addition, labels should not be labeled with too much information to ensure clear readability. Taking these factors into account can ensure the readability of cryogenic labels in cryogenic conditions.